Water-based steam cleaning may seem like a fast and efficient way to keep a stone floor spotless but repeated use of super heated water can potentially cause issues. These include residual staining, mobilisation of salts and corrosion of hidden particles of Iron within some limestone surfaces.

Repeated cleaning using a steam cleaner can activate salts and weaken the stone over time. This can also lead to spalling or fragmentation of the surface.

COMPROMISED IMPREGNATING SEALER?

COMPROMISED IMPREGNATING SEALER?Surfaces that have been treated with an impregnating sealer can also be compromised. Steam cleaning doesn’t normally remove the finish but repeated use can expose new fissures and capillaries within the stone. The newly exposed and unsealed surface takes in more dirt and becomes harder to clean, so then requires more frequent cleaning. This increase in cleaning can then, in turn, exacerbate the problem.

SURFACE SEALER DAMAGE

Topical sealers used to finish the surface of stone can also be damaged.Steam is often used to remove paints, wall papers and othercoatings from surfaces. If a film-forming sealer has been used then the steam can cause a partial separation of the seal from the surface of the stone, causing it to turn white or opaque.

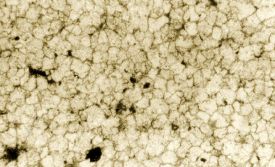

CRUMBLING OF THE SURFACE?

Moisture from repeated steam cleaning can, in some

cases, cause spalling or fragmentation of the surface.

The migration of salts from moisture in the limestone can promote crumbling of the surface causing larger fissures and craters to appear. This is more

common in limestone and marble that contain naturally occurring mud or calcite veins which are more vulnerable to this issue.

WHAT TO DO?

COMPROMISED IMPREGNATING SEALER: Intensively clean the surface of the stone with LTP Grimex. Leave overnight to dry. Re-apply impregnating sealer – LTP Mattstone H2O or LTP Colour Intensifier & Stainblock H2O. For routine aftercare use LTP Waxwash. This is a PH neutral cleaner that will not damage the stone or compromise the seal.

SURFACE SEALER DAMAGE: Remove the film forming sealer using LTP Grimex or LTP Solvex. Leave overnight to dry. Re-apply the film forming sealer – LTP Ironwax Satin or LTP Ironwax Gloss. For routine aftercare use LTP Floorshine. This gentle detergent will clean the stone and repair the seal where it has worn from abrasion every time the floor is washed.

RUST STAINS ON THE SURFACE: Intensively clean the surface of the stone with LTP Power Stripper or specialist treatment, LTP Ferrex. Leave overnight to dry. Re-apply impregnating sealer, as above. For routine aftercare use LTP Waxwash.

CRUMBLING OF THE SURFACE: Intensively clean the surface of the stone with LTP Grimex. Leave overnight to dry. Use a suitable colour-matched resin stone filler to fill in the voids. Re- hone the surface of the stone using a twister pad and sponge down with a little water to remove any dust or sediment. Leave to dry. Re-apply impregnating sealer, as above. For routine aftercare use LTP Waxwash.

This information is offered without guarantee. The material should be used so as to take account of the local conditions and the surfaces to be treated. In case of doubt, the product should be tried out in an inconspicuous area.